AirVerter – A Division of Smith Eastern Corporation

CAPS

Capture Air Pollutants System (CAPS) –

Capture, Contains, Controls

A Paint Booth in the palm of your hand!

CAPS portability is the answer to the challenge of working out of booth when addressing small spot painting and or small repair jobs providing the ability to control, contain and filter hazardous air pollutants.

With the new enhancement of the Peterson Plug on the PAPCE, now included on all PAPCE’s, this allows the PAPCE to function in the same way as CAPS, still portable, but even more powerful.

Dual Cone

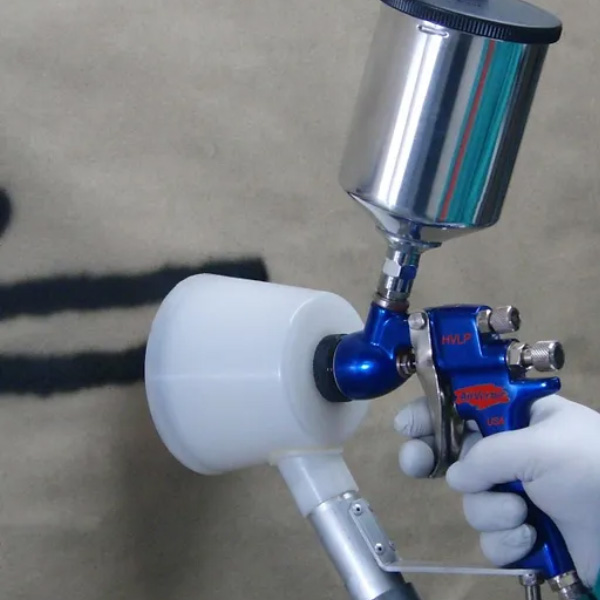

Our Dual Cone design delivers equal suction around the entire perimeter of the outer cone in order to capture overspray right at the source.

Microflex & CAPS II "Duo"

Have the best of both worlds! Don’t let over overspray management cost you valuable time. Don’t waste coating any longer flooding those difficult to reach places. Now you can solve both problems at the same time! This “Duo”saves ergonomic strain of reaching nooks, is transfer efficient, tested above 90%, and perfect for bolt heads and seams.

CAPS Spray System with PAPCE

Airverter’s PAPCE combines with our CAPS eqipment allows overspray along with fume containment and collection at the point of generation at the same time up to 25 feet from the main unit. Quick and easy disconnect for cleaning and storage.

CAPS with Sharpshooter Spray Paint Gun

Designed for fine detail work. Great for rivet heads and other fasteners.

CAPS Overspray Reduction System

Captured Air Pollutants System II, CAPS overspray reduction/evacuation products for spot painting and small repair jobs. The CAPS family of spray and filtration units was developed in 2006. CAPS made overspray reduction and fume capture available in an even more portable tool-chest sized cabinet. Refinements improved the transfer ratio of paint, especially for small parts coating on site.

Upon atomization the coating is contained within the cone. Overspray and fumes are collected and evacuated through the Intake Hose and directed into the Filter Housing. The contaminated air is then processed through a NESHAP Compliant Filter Arrangement and expelled through the Exhaust Hose using a Pneumatic Airflow Device in the Controller Unit.

The air may then be discharged into the workplace or directed through an Exhaust Duct.

US Patented

How Our Technology Help You.

This system at first glance appears to be a four-tier piece of machinery on a portable cart, with three storage drawers. However, the heart of the system itself sits on the top where it can be easily picked up and carried. This lightweight heavy hitter uses our HVLP guns, Sharpshooter, “Dual Cone” or “Duo” technology and can control, contain, and evacuate hazardous overspray before it can escape. (see video) Like our PAPCE system, the CAPS system filtration system meets EPA and AQMD compliancy and works with our HVLP guns and various attachments for a complete air quality management package. Whether you’re out on the tarmac, out on a port dock, inside a fuselage or in very small quarters like a submarine, this system gets the job done. Unlike the PAPCE, this system is powered by Pneumatics.

Contact Us

10630 Riggs Hill Road, Suite S

Jessup, Maryland 20794-9425 USA

301.497.7600

1.800.937.HVLP

info@airverter.com

Hours of Operation

Saturday/Sunday: Closed

Monday – Friday: 8am to 5pm

Veteran Owned Small Business (VOSB)

Made in the USA